Industry 4.0: The Fourth Industrial Revolution in Manufacturing

Over the years, we have witnessed remarkable advancements in technology that have revolutionized various industries, and the manufacturing industry is no exception. Today, we stand on the precipice of the Fourth Industrial Revolution – Industry 4.0 – a digital transformation that promises to reshape manufacturing as we know it.

So, what does Industry 4.0 really mean? At its core, it refers to the integration of digital technologies into manufacturing processes to enable the development of smart factories. These factories will not only be equipped with state-of-the-art machinery and equipment but will also leverage artificial intelligence, machine learning, the Internet of Things (IoT), and big data to enhance productivity, efficiency, and overall quality.

One of the key aspects of Industry 4.0 is the concept of interconnectedness. In smart factories, all components, systems, and processes are connected through a network, enabling seamless communication and data exchange between them. This connectivity allows manufacturers to have real-time visibility and control over their entire production line, facilitating timely decision-making and reducing downtime.

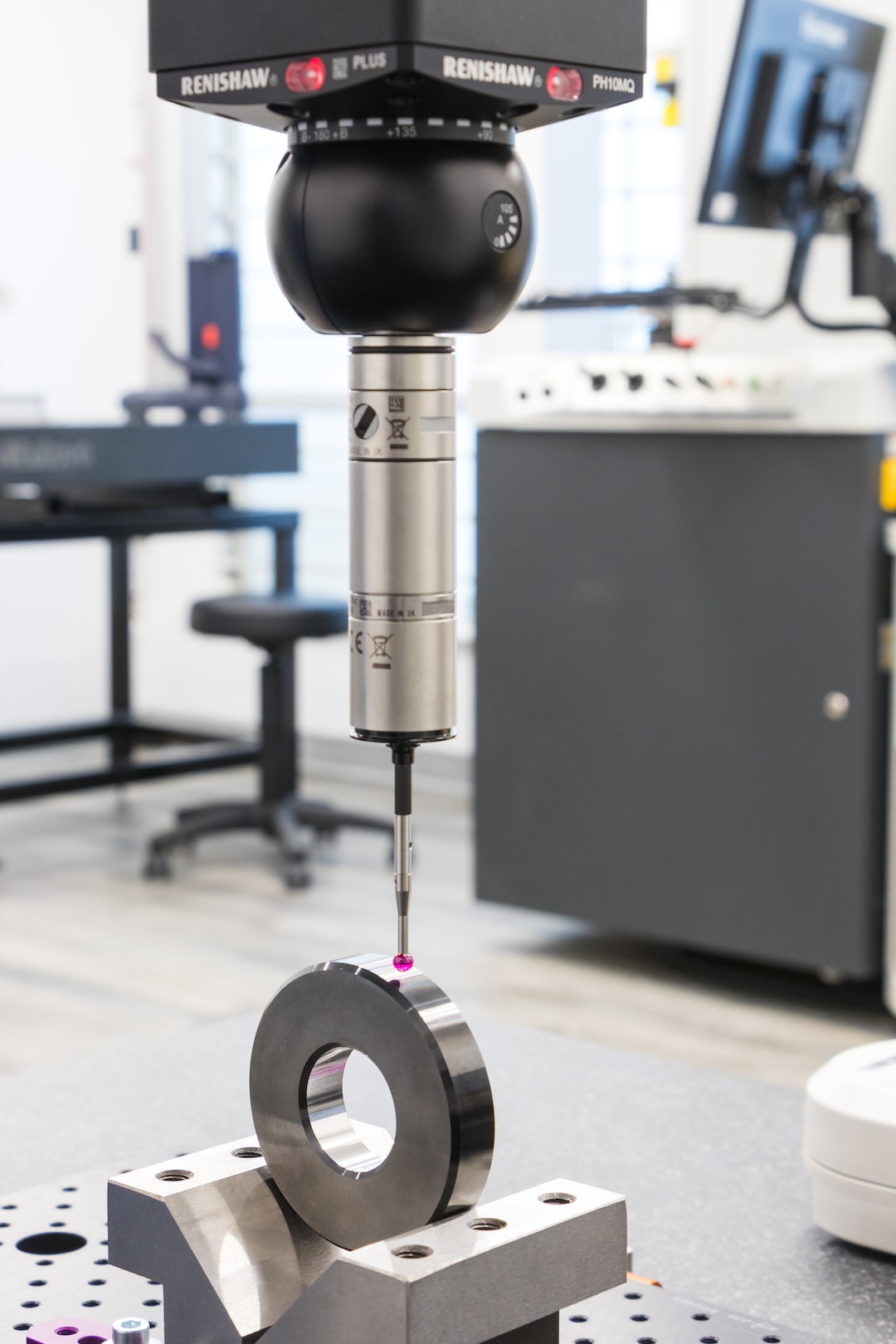

The use of IoT devices in Industry 4.0 is particularly noteworthy. These devices, which include sensors, actuators, and RFID tags, collect and transmit data throughout the factory. This data is then analyzed, providing insights that can help optimize processes, predict maintenance needs, and identify opportunities for improvement. For instance, sensors on a machine can detect anomalies in its performance and automatically alert maintenance personnel, minimizing unplanned downtime and costly repairs.

Moreover, the integration of artificial intelligence and machine learning algorithms enables machines to learn from data, continuously optimize their performance, and make informed decisions autonomously. This not only boosts productivity but also minimizes human error and frees up employees to focus on more strategic and creative tasks. Additionally, machine learning algorithms can identify patterns and trends in data, allowing manufacturers to make data-driven decisions, optimize inventory management, and forecast demand more accurately.

Data plays a crucial role in Industry 4.0, and the ability to collect, analyze, and leverage big data is a fundamental requirement for its success. Manufacturers can gather large volumes of data from various sources, including machines, equipment, products, and customers. This data can be utilized to gain insights into customer behavior, improve product design, enhance supply chain efficiency, and enable predictive maintenance. However, managing and interpreting this vast amount of data poses a significant challenge that companies must address.

Although Industry 4.0 offers numerous benefits, it also raises concerns about its impact on the workforce. As machines become increasingly autonomous and intelligent, the need for manual labor diminishes, potentially leading to job redundancies. However, this revolution also creates new job opportunities, particularly in the fields of data analysis, cybersecurity, software development, and systems integration. To fully embrace Industry 4.0, organizations must invest in upskilling their workforce and promoting a culture of continuous learning.

The transition to Industry 4.0 requires collaboration and cooperation across industries, academia, and governments. To ensure the successful adoption of this revolution, policymakers need to create an enabling environment that supports research and development, invests in necessary infrastructure, and promotes digital literacy. In turn, industries must be willing to embrace change, invest in technology, and foster a culture of innovation.

In conclusion, Industry 4.0 promises to drive a new era of manufacturing, characterized by smart factories that leverage advanced technologies to optimize processes, enhance productivity, and reduce costs. Digital transformations, such as the integration of IoT, artificial intelligence, machine learning, and big data analytics, empower manufacturers to make informed decisions and adapt to an ever-changing marketplace. However, to fully realize the potential of Industry 4.0, organizations must be willing to invest in technology, upskill their workforce, and embrace a culture of innovation. Industry 4.0 is more than just a technological shift; it is a paradigm shift that requires collaboration and cooperation to shape the future of manufacturing.